The engineering jobs contain calculations and simulations of TORSIONAL VIBRATIONS of straight, branched, and intermeshed drive systems (drivelines, powertrains) also considering nonlinear characteristics (e.g. rubber couplings, gear stages with backlash, shift and engage effects in clutches, etc.) in the time or frequency domain. We can follow steady-state conditions or time-transient effects in the simulation environment. Furthermore, control effects may be part of an expanded torsional vibration model.

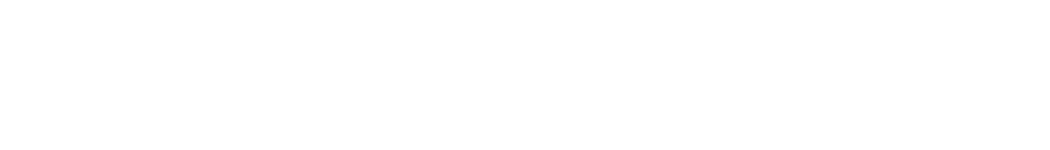

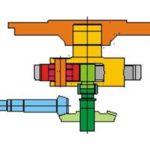

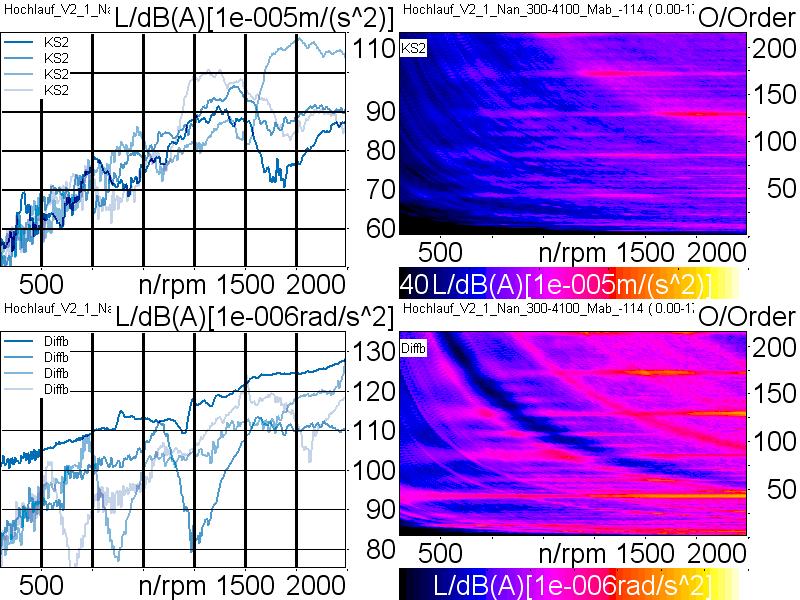

The CAE results show the natural frequencies (critical speeds) usually presented in so-called „Campbell“ diagrams (interference diagrams, waterfall diagrams), as well as the graphical interpretation of the vibration modes (modular forms, mode shapes). We also get simulation results showing the expected amplitudes and magnitudes (usually taken from torque signals, velocities and speeds, accelerations) depending on the existing excitations (i.e. excitation torques of the motor, the engine, the working process, and the operating conditions).

A typical torsional vibration analysis (TVA) is structured as follows:

We distinguish between two different simulation methods for our CAE analysis:

a) the „STEADY-STATE SIMULATION“ (i.e. the simulation of the steady-state operating condition with constant operating speed also known as „simulation in the frequency domain“)

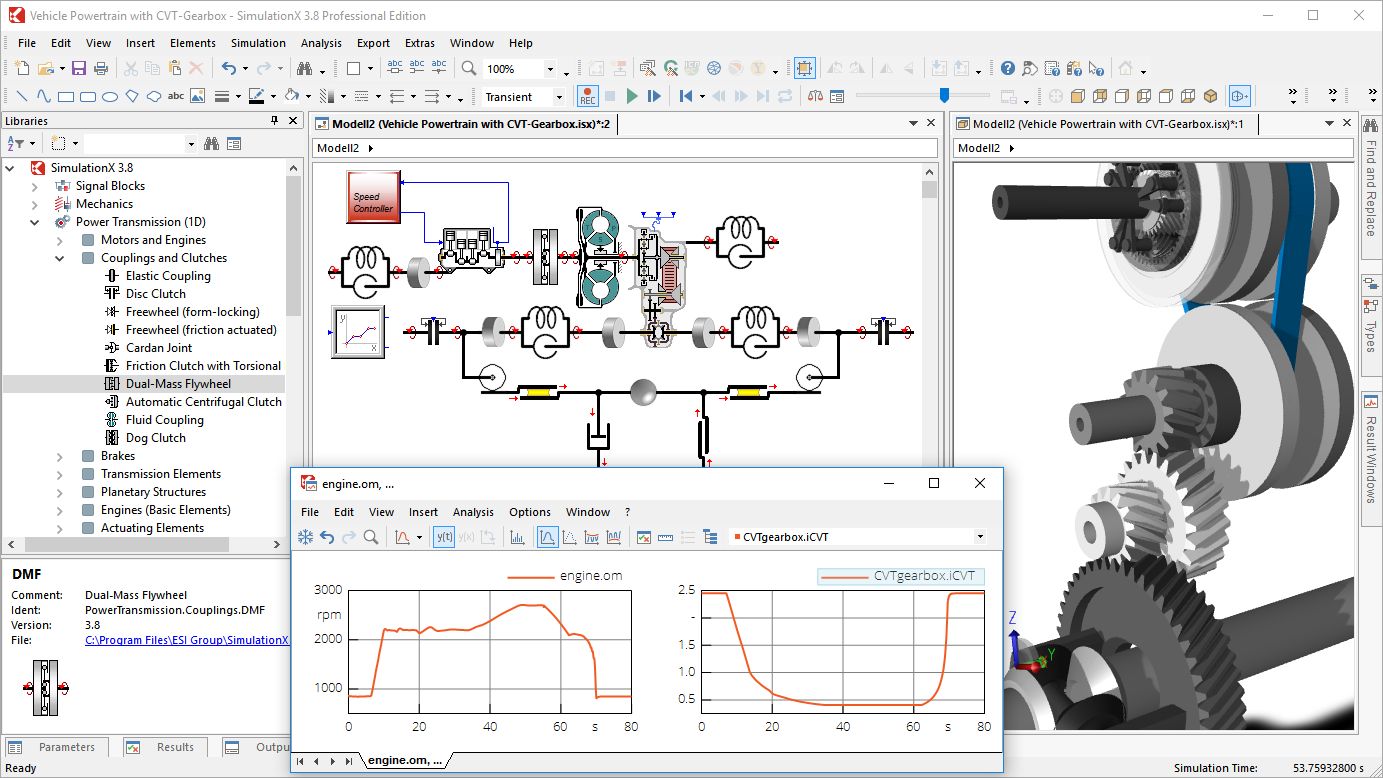

b) the „TIME-TRANSIENT SIMULATION“ (i.e. the „simulation in the time domain“ to determine the time-transient response of the drive system depending on time-variable operating conditions also considering nonlinear effects like gear backlash)

Possible resonances can be predestinated („simulated“) – similar to a „weather forecast“ of the dynamic behavior of the complete drive system (driveline, powertrain); here: example of a reciprocating compressor driveline.

Even dynamic-acoustic effects can be predicted as part of so-called NVH studies (NVH = „Noise, Vibration, Harshness“) which are important when optimizing automotive drivelines and complete powertrains (cars, trucks, any other vehicles). Special references and extended information particularly on this subject are available on request.

Source: ESI-ITI, Dresden / Germany (Software: SimulationX)

Source: ESI-ITI, Dresden / Germany (Software: SimulationX)

We would like to offer our best custom-tailored engineering service concerning your current project. Please send us your inquiry (submission of your inquiry).

More detailed information concerning all the other subjects are available as well.

Please contact us.

Analysis especially of lateral and flexural vibrations including a stability analysis of rotor bearing systems in rotating machinery supported by the software ARMD. Learn more …

The virtual development process requires suitable R&D software tools, simulation environment, measurements, field tests, experiences. Learn more …

Publications by Dr. Andreas Laschet: technical papers in journals, conference papers, book contributions. Learn more …

This is our customer support to get you started: compilation of important questions and our answers. Learn more …

Free webinars as online support to discuss important topics in the engineering field. Learn more …

International engineering seminars in close cooperation with RBTS, Inc. More information available: Detailed Seminar Program & Online Registration …

Do you already know our new HELP AREA (Support - Questions & Answers)?

This link will take you there immediately:

Our next Vibration Seminar is planned again for 2024. We will inform you in time about the contents, the exact date and registration possibilities.

Click here to go straight to our latest WEBINARS for engineers:

Free Webinars: HIGHLY RELEVANT

We would like to offer our best custom-tailored engineering service concerning your current project. Please send us your inquiry (submission of your inquiry).

Downloads (PDF):

Do you already know our new HELP AREA (Support - Questions & Answers)?

This link will take you there immediately:

| Cookie | Description |

|---|---|

| Necessary / Notwendig | |

| CookieLawInfoConsent | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| cookielawinfo-checkbox-analytics | Set by the GDPR Cookie Consent plugin, this cookie records the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-performance | Set by the GDPR Cookie Consent plugin, this cookie stores the user consent for cookies in the category "Performance". |

| viewed_cookie_policy | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| cookielawinfo-checkbox-necessary | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-non-necessary | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Non Necessary". |

| Non Necessary / Nicht notwendig | |

| test_cookie | This cookie is set by doubleclick.net. The purpose of the cookie is to determine if the users' browser supports cookies. |

| Analytics / Analytik | |

| _ga_* | Google Analytics sets this cookie to store and count page views. |

| _ga | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, camapign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assigns a randoly generated number to identify unique visitors. |

| _gid | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the wbsite is doing. The data collected including the number visitors, the source where they have come from, and the pages viisted in an anonymous form. |

| Performance / Leistung | |

| _gat | This cookies is installed by Google Universal Analytics to throttle the request rate to limit the colllection of data on high traffic sites. |

Phone: +49 2204 84-2630 • Fax: +49 2204 84-2639 • Email: info@laschet.com • Web: www.laschet.com

HOME – ABOUT US – ENGINEERING – WEBINARS – SEMINARS – TECHNICAL CONSULTING – CONTACT

Site Notice – Privacy Policy – Information Obligation – Cookie Manager – Legal Notices